- Home

- Services/IndustriesServicesindustries

- About Us

- LocationsStatesAccordion ContentAccordion ContentAccordion ContentAccordion Content

- Job Openings

- Quick Links

- ATS Family

Adhesion Testing

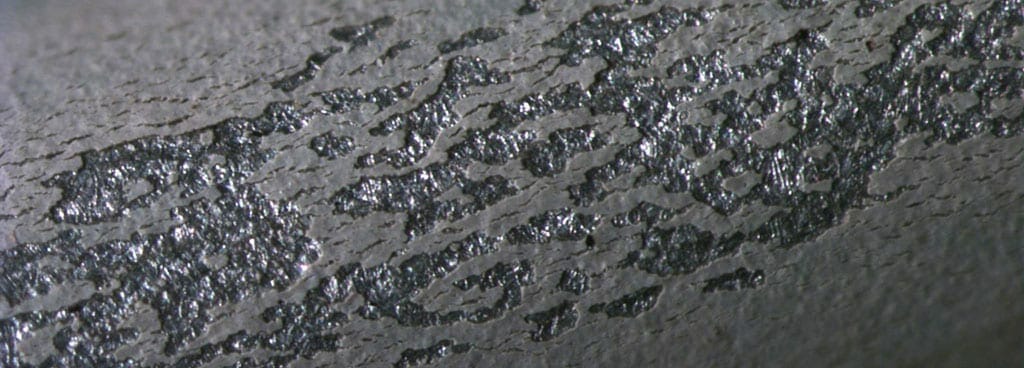

ATS conducts Adhesion testing to determine if adhesives can properly adhere to a layer. But not all paints, glues, or other adhesives stick to all substrates in the same way. Surface preparation, or lack thereof impair effective bonding between the two materials. Since there is no immediate visual cue when that happens, the bond’s adhesion must be tested to ensure that it performs to satisfactory standards when placed in service. Adhesion, the measure of how well the fixative has bonded to its substrate, is evaluated through adhesion testing. This information can be used to determine the failure point of the adhesive — the least amount of duress which will cause the product to fail — for quality control and safety purposes.

Adhesion Testing Methods Include:

Cross-Cut Test: accomplished by cutting into the adhesive (all the way down to the substrate) in one of two patterns with a utility knife, applying pressure-sensitive tape over the area, and quickly pulling it off

- Quick

- Qualitative

- Results are either pass/fail or judged on a 0–5 scale

- Can be performed with a knife and pressure sensitive tape

- Used specifically for paints and coatings

- ASTM D3359 standard testing method (ISO 17025 (A2LA) Accredited)

Scrape Test: accomplished by using balance-beam scrape-adhesion tester to scrape adhesive off the substrate by way of a rounded stylus applied with increasing amounts of pressure

- Cannot be performed on-premises

- Laboratory Setting

- Quantitative

- Can only be performed on flat material

- Used for paints, coatings, varnishes, and lacquers

- ASTM D2197 standard testing method

Pull-Off Test: achieved by sticking a dolly to the test material and pulling it off with a machine

- Measures the amount of pressure it took to remove the dolly (adhesive layers and all)

- Can instead stop at a predetermined value

- Applies tensile load instead of shear load

- Meaning these results are a measure of a different value than the previous two tests

- Could be performed on-site

- Quantitative

- More variables apply than with other tests

- Used for any coating on a flat surface

- ASTM D4541 and ISO 4624 standard testing methods

Each of these tests may be performed at multiple temperatures to account for the materials that expand or contract due to heat. These factors can also play a role in the test materials’ adhesion to its substrate. Although other standards can be used to perform adhesion testing, the methods listed above are the most commonly used.

Applied Technical Services Does All This and More!

For over 50 years, we have been providing materials testing, equipment inspections, and structural analysis services to our satisfied clients. We at ATS have a collection of certifications and accreditations that qualify us to take care of a variety of client needs, including any adhesion testing they may require to be performed.

Request Form

"*" indicates required fields